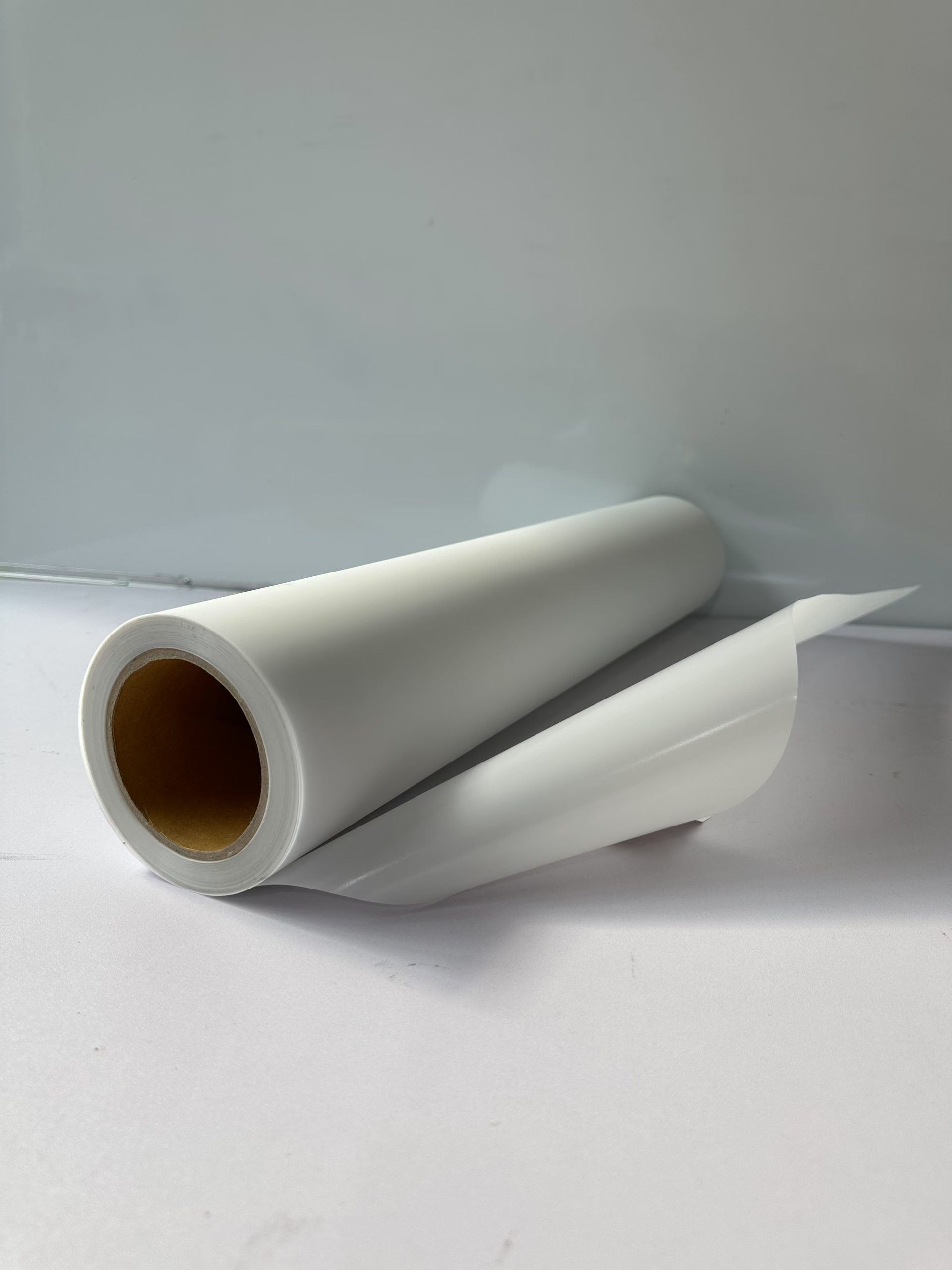

Wholesale UV dtf film

HaiYi Material is a professional factory to manufacture UV DTF transfer film, Direct to Film transfer. It can be used for T shirt pattern printing. It can meet Personalized needs. We produce and export to many countries, like Europe, North America, Southeast Asia. etc. Good price and High quality, Stable formulation, advanced coating technology and intime after sales service,which makes HaiYi products become more and more competitive.

Description

HaiYi UV DTF FILM is a DTF (Direct to Film) transfer film material combined with UV curing technology. The ink is instantly cured by ultraviolet irradiation to form a pattern layer with high adhesion. Its core advantage is to improve the scratch resistance, washability and color expression of the printing.

Applicable fabrics

Natural fibers: cotton, linen, silk (best effect when the cotton content is ≥50%).

Blended fabrics: cotton-polyester (65/35), polyester-cotton (35/65).

Synthetic fibers: polyester (requires coating pretreatment), nylon (needs to test adhesion).

Special fabrics: suede, lightly coated Oxford cloth (needs to be adapted to pretreatment agents).

Note: Dark fabrics need to be printed with a white background first, or choose “priming white ink + CMYK” double-layer printing.

Usage steps

Design and color separation

Use RIP software to process the pattern and generate a CMYK+white channel file (supports spot colors or fluorescent colors).

Complex patterns need to be printed in blocks, and a 2-3mm overlap area is reserved for splicing.

UV printing film

Print the pattern onto the PET release film through a UV printer (white ink as base, UV ink curing).

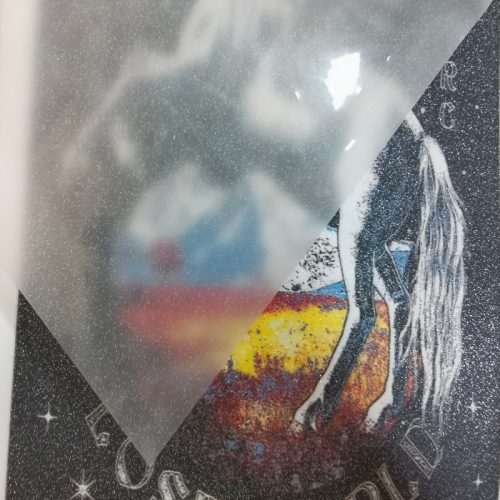

After printing, you can choose to apply matte/glossy film to enhance the touch and wear resistance.

Heat transfer operation

Equipment: flat heat press (recommended temperature 140-150℃, pressure 4-5kg).

Steps:

a. Place the T-shirt and cover it with a high-temperature cloth (avoid direct contact with the fabric).

b. Align the position with the pattern facing down and heat press for 12-15 seconds.

c. Tear off the film after cooling to complete the transfer.

Post-curing

For highly elastic fabrics, UV lamps can be used for 30 seconds to improve the tensile durability.

Core advantages

Extreme scratch resistance

The hardness of the UV cured layer reaches 3H, which can resist daily friction such as nails and keys.

Color expression

Supports high-saturation colors and gradient effects, and the color gamut covers 90% of Adobe RGB.

Super fast delivery

UV ink dries immediately after printing, no need to wait for drying time, suitable for rush order production.

Environmentally friendly and safe

UV ink does not contain VOCs and meets OEKO-TEX® certification standards.

Strong compatibility

Can be transferred to special fabrics such as polyester and nylon through pretreatment agents.

Applicable ink types

UV curing ink: The main component is photosensitive resin, which needs to be cured with LED-UV light source.

Features: instant curing, high hiding power, good outdoor weather resistance.

Brands: Such as Mimaki UJF series, Roland ECO-UV ink.