DTF PET transfer film

HaiYi Material is a professional factory to manufacture DTF PET transfer film, Direct to Film transfer. We produce and export to many countries, like Europe, North America, Southeast Asia. etc.Good price and High quality, Stable formulation, advanced coating technology and intime after sales service,which makes HaiYi products become more and more competitive.

Description

DTF PET Transfer film, or polyethylene terephthalate transfer film, is a plastic film that is mainly used to transfer text and patterns on other films or stickers to the surface of another object, playing a temporary bearing role.

1. Advantages of HaiYi water-based DTF PET transfer film

Soft feel: The pattern after heat transfer has the texture of PU glue, which is softer than glue and usually 30%~50% softer than the pattern printed by oil-based coating film.

Strong adaptability: It can adapt to most inks on the market, and 100% of the ink can be printed at will without ink gathering or flowing.

Convenient operation: The surface of the film is dry and can be easily torn hot, cold or even in seconds to meet different operation requirements.

Stable quality: The most cutting-edge core key technology in the industry is adopted to control the stability of quality and ensure the consistency of printing effect.

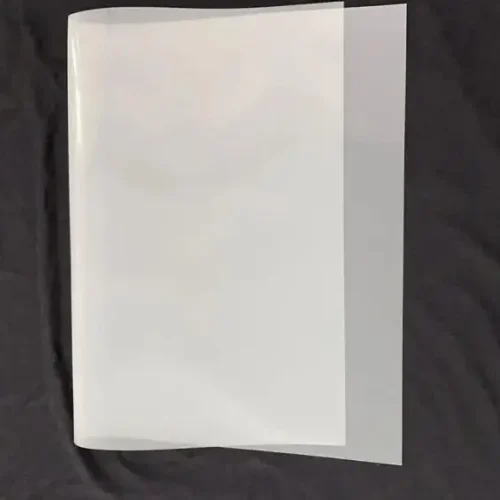

The difference between single-sided film and double-sided film

Structural difference: The double-sided film has an extra layer of coating in structure compared with the single-sided film, which makes the double-sided film slightly superior in thickness, while the single-sided film appears thinner.

Double-sided film: More suitable for users who use old white ink heat transfer machines, it can effectively prevent the problem of slipping of the heat transfer film or arching the paper to scrape the nozzle. The double-sided film improves the stability of the printing process by increasing friction.

Single-sided film: For users who own the new three-wheel white ink heat transfer machine, both single-sided and double-sided films can be easily handled with equally excellent printing effects.

How to use DTF PET transfer film

Prepare materials: Prepare the PET transfer film and the target object, and ensure that the surface of the target object is clean and smooth.

Cutting and positioning: Cut the PET transfer film into appropriate sizes as needed and position it on the target object to ensure the accurate position of the pattern or text.

Heating and transfer: Use a thermal transfer machine or other heating equipment to heat the PET transfer film so that the adhesive between it and the carrier softens and transfer occurs. The heating temperature and time should be adjusted according to the specific materials and requirements.

Peeling and finishing: After the pattern or text is completely transferred to the target object, gently peel off the PET transfer film and finish the target object to ensure the integrity and clarity of the pattern or text.