Double Matte DTF PET Film

As one of the leading manufacturers of double matte DTF PET film in China, HaiYi has rich production experience and R&D strength, and is able to provide wholesale and customized products and services according to customer needs. With a wide range of products, including double matte DTF PET film in different specifications and sizes, HaiYi can always provide you with the best solution. Just send us your detailed requirements to get an instant quote.

Description

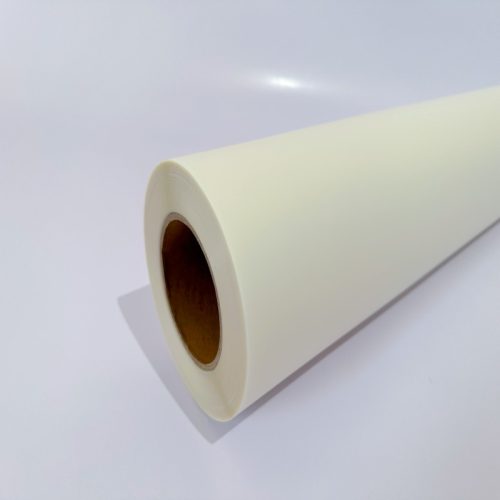

Double matte DTF PET film is a double-sided matte thermal transfer film made of PET (polyethylene terephthalate) material. This film is designed for thermal transfer printing and has double-sided matte properties, which can provide a soft and uniform visual effect. It is usually used for personalized pattern printing on clothing, textiles and other items. It can transfer high-precision images and text from the film to various substrates, with bright colors, fine patterns, washability and wear resistance. Double Matte DTF PET Film has a wide range of applications in the field of thermal transfer, which can meet the needs of personalized customization and mass production.

| Product Name | Double Matte DTF Film | Thickness | 75 Micron |

| Model NO. | HY-SY | Weight | 15KGS |

| Material | PET | Package | 2 Rolls/Carton |

| Type | Heat Transfer | MOQ | 1 Roll |

| Size | 60CM*100M 30CM*100M | Carton size | 620*290*145MM |

| Transfer Temperature | 150-160℃ | Brand Name | HaiYi |

| Transfer Time | 10 Seconds | Origin | Guangdong, China |

| Peeling Method | Cold and Hot Peel | Application | sportswear, T-shirts,Textiles, Clothing, |

1. Core advantages

High viscosity and durability: DTF transfer film can maintain high viscosity during the transfer process, so that the pattern is firmly attached to the fabric, has good durability, and can adapt to use in various environments.

Bright colors and high clarity: The printing effect of white ink heat transfer film is excellent, with bright colors and clear layers, especially suitable for large-area pattern printing.

Wide application: It is suitable for various types of fabrics, such as cotton, linen, polyester, etc., providing designers with rich creative space. At the same time, DTF transfer film is also suitable for printing outdoor leisure products, such as luggage, leather, glass, ceramics and other polyester printed fabrics.

2. Materials and production

Required materials: The materials required for white ink heat transfer mainly include white ink, hot melt powder, DTF PET film, DTF ink, etc. Among them, white ink is the basic color that constitutes the white background of the printing film, and the remaining color inks are used to print patterns on the film.

Production process:

The production process of DTF transfer film is simple. Only a dtf printer is needed, and the heat transfer process can be completed through computer operation. Design the pattern to be produced on the computer, use the drawing software to process the image, and then print the pattern to be hot-stamped with the white ink heat transfer machine. No plate making and no waste discharge are required. The printed heat transfer film is dusted, shaken, dried and solidified by the powder shaking machine to obtain the finished white ink heat transfer film.

Application and effect

Application field: The application field of DTF transfer film is very wide, covering many industries such as clothing, shoes and hats, accessories, toys, and gifts. In the field of clothing, white ink heat transfer technology is widely used in the production of printed trousers, theme packaging, sports equipment and other products.

Printing effect: The patterns printed by the white ink heat transfer process are rich in layers and bright in color. The printing effect is comparable to photos and can meet customers’ requirements for high-quality patterns. Whether it is a pattern, font, logo or photo, it can be transferred to clothing or other fabrics through white ink heat transfer technology to meet personalized customization needs.

Types and selections

Types: From a process perspective, DTF transfer film can be divided into single-sided films and double-sided films. Double-sided films have one more layer than single-sided films, and the process is more stable and the powder is shaken more cleanly. From a release perspective, white ink heat transfer films can be divided into three types: instant peel(hot peel), warm peel, and cold peel.

1. Warm peel film: After the hot stamping is completed, the PET heat transfer film can be torn off before it cools down (usually within 10 seconds after hot stamping, when the ambient temperature is 35°C or the film surface temperature is greater than 100°C). Using hot tear film can save time waiting for the heat transfer film to cool down and improve the efficiency of mass production printing. However, if it is not torn off in time, the cooled glue may stick to the clothes, making it difficult to tear off, and even causing problems such as pattern residue.

2. Cold peel film: After the hot stamping is completed, the PET heat transfer film needs to wait for the film to cool down to a certain temperature (usually 30 seconds, or the film surface temperature is lower than 55°C) before it can be easily torn off. Cold tear film requires a certain cooling time, but the product stability is better and the color effect is matte. Cold tear film is very suitable for special fabrics (such as coated fabrics, canvas, flannel and other rough fabrics).

3.Instant Hot peel film: PET heat transfer film that can be torn off in a very short time (almost immediately after the pressing is completed). Due to its fast tearing characteristics, the second tear film may be more suitable for scenes that require high efficiency and large-scale production. However, it has strict requirements on the tearing time and is more difficult to operate.

Choose the appropriate type of DTF transfer film according to actual production needs. For example, hot peel film or instant peel film can be selected for mass production, and cold peel film can be selected for special fabrics.