Best DTF Film

HaiYi Material is a professional manufacturer and supplier of DTF film. We are one of best dtf film manufacturers in China. We produce regular DTF film and special DTF film, like jumbo roll and cut roll both available. We can offer kinds of different size and specifications with competitive price. We have rich production and exportation experience. Apart from DTF film, but also supply other heat transfer film materials. Welcome to contact us.

Description

HaiYi DTF Film is one of best dtf films in the market. and HaiYi is the first batch and professional factory to produce best dtf film. Not only jumbo roll, but also supply cut roll. Jumbo roll width is generally 1215mm and length can be 4,000m or 6,000m or can be customized as per requested.

HaiYi DTF film (taking high-quality products as an example) usually has the following advantages:

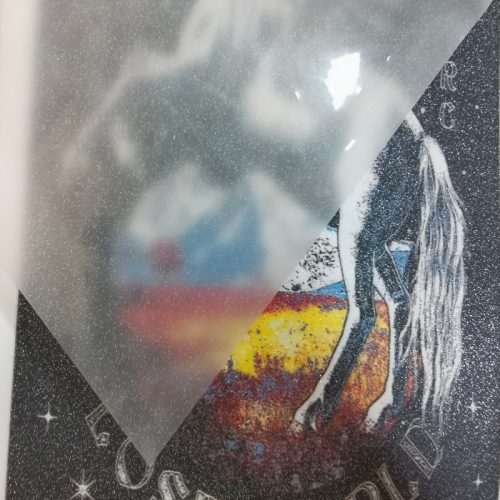

Bright colors: using advanced printing technology, it can present rich colors, ensuring that the printed pattern is full of color and clear in details.

High precision: the printing precision is extremely high, which can meet the application scenarios with high requirements for details.

Washable and wear-resistant: it has good wash fastness and wear resistance, ensuring that the pattern can still maintain clarity and color vividness after multiple washings.

Wide applicability: it is suitable for a variety of fabrics and materials, including but not limited to pure cotton, polyester, nylon, leather, etc., and can even be used on hard surfaces such as glass, wood and metal.

Specifications

DTF film has various specifications, which may include but are not limited to the following common sizes:

Width: standard sizes such as A3 and A4, as well as specific widths such as 30cm, 33cm, 37cm, 60cm, etc.

Length: can be customized according to needs, usually in rolls.

Thickness: DTF films of different thicknesses are suitable for different application scenarios and substrate characteristics.

Applied fabrics

DTF film is widely used on a variety of fabrics, including but not limited to:

Pure cotton fabric: has good moisture absorption and breathability, and is a common fabric for T-shirts, shirts and other clothing.

Polyester fabric: has the characteristics of wear resistance and wrinkle resistance, and is often used in sportswear, outdoor clothing, etc.

Nylon fabric: has the characteristics of high strength, wear resistance, good elasticity, etc., suitable for swimsuits, sportswear, etc.

Leather fabric: such as synthetic leather or genuine leather, can be used for the decoration of products such as shoes, bags, and furniture.

Usage process

The use process of Using HaiYi DTF film usually includes the following steps:

Design pattern: Use design software to outline the pattern to be printed and adjust it to the appropriate size and resolution.

Printing preparation: Install the DTF film on the DTF printer, making sure that the printing surface (usually the ink-absorbing coating surface) faces up.

Printing pattern: Print the designed pattern directly onto the DTF film through the DTF printer. During the printing process, it is necessary to ensure that the printer settings match the specifications of the DTF film.

Drying: After printing, let the DTF film dry naturally or use drying equipment to accelerate the drying process to ensure that the ink is completely cured.

Preheating and starting: Adjust the temperature of the thermal transfer machine to an appropriate range and preheat for a period of time to ensure that the machine reaches a stable working state.

Fabric preparation and alignment: Lay the fabric to be printed flat to ensure that there are no wrinkles and impurities. Then place the DTF film accurately on the fabric with the pattern facing down to ensure correct alignment.

Hot pressing and shaping: Send the fabric and DTF film together into the thermal transfer machine for hot pressing and shaping. Parameters such as hot pressing time, temperature and pressure need to be adjusted according to the specifications of the DTF film and the characteristics of the substrate.

Cooling and curing: After hot pressing, let the pattern cool naturally or cool it quickly so that the pattern is more firmly attached to the fabric.

Tear off the film: After cooling, gently tear off the backing layer of the DTF film (if any), and you can see that the pattern has been perfectly transferred to the fabric.